Design and planning of sheet metal molds

OLMECSRL is specialized

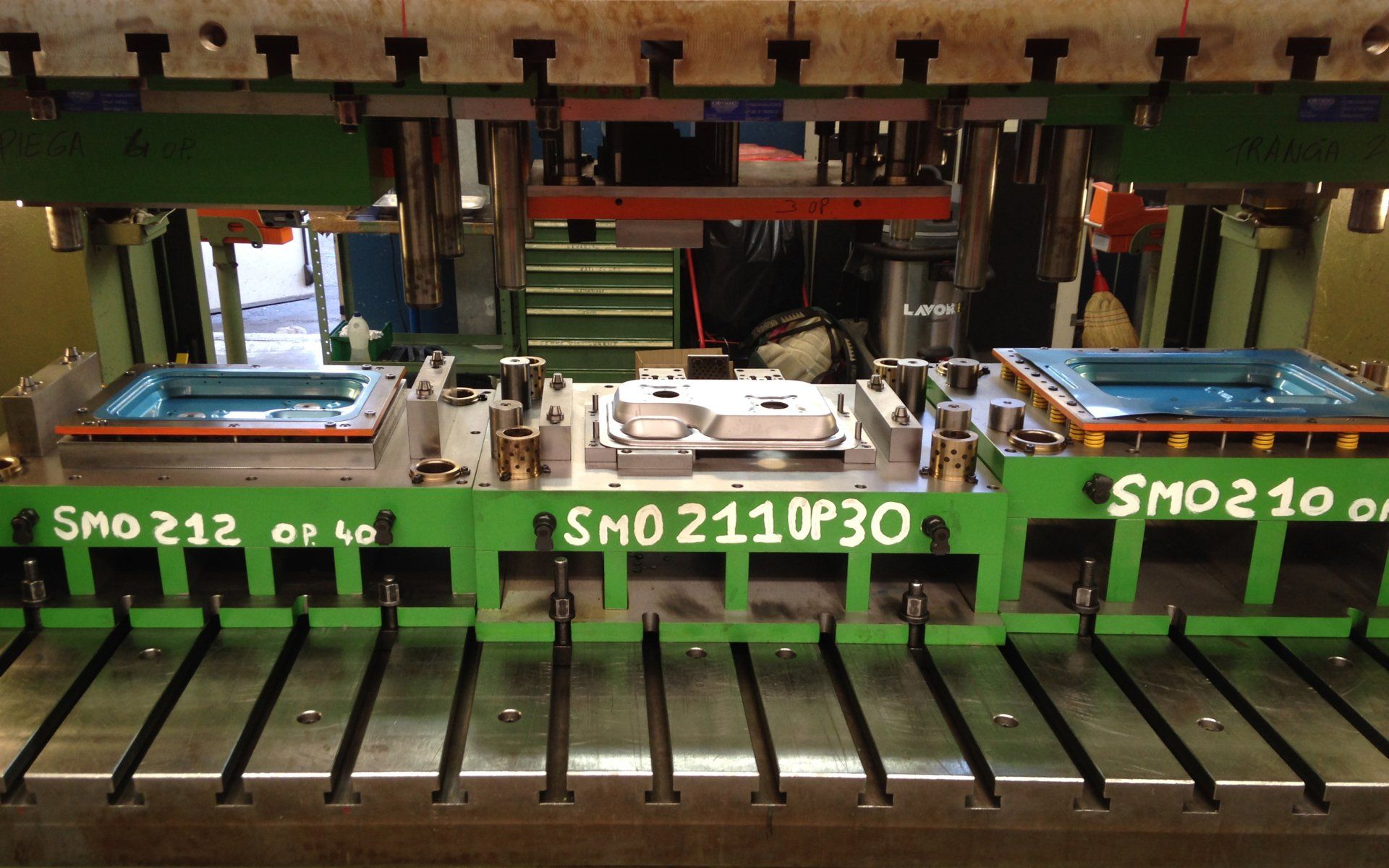

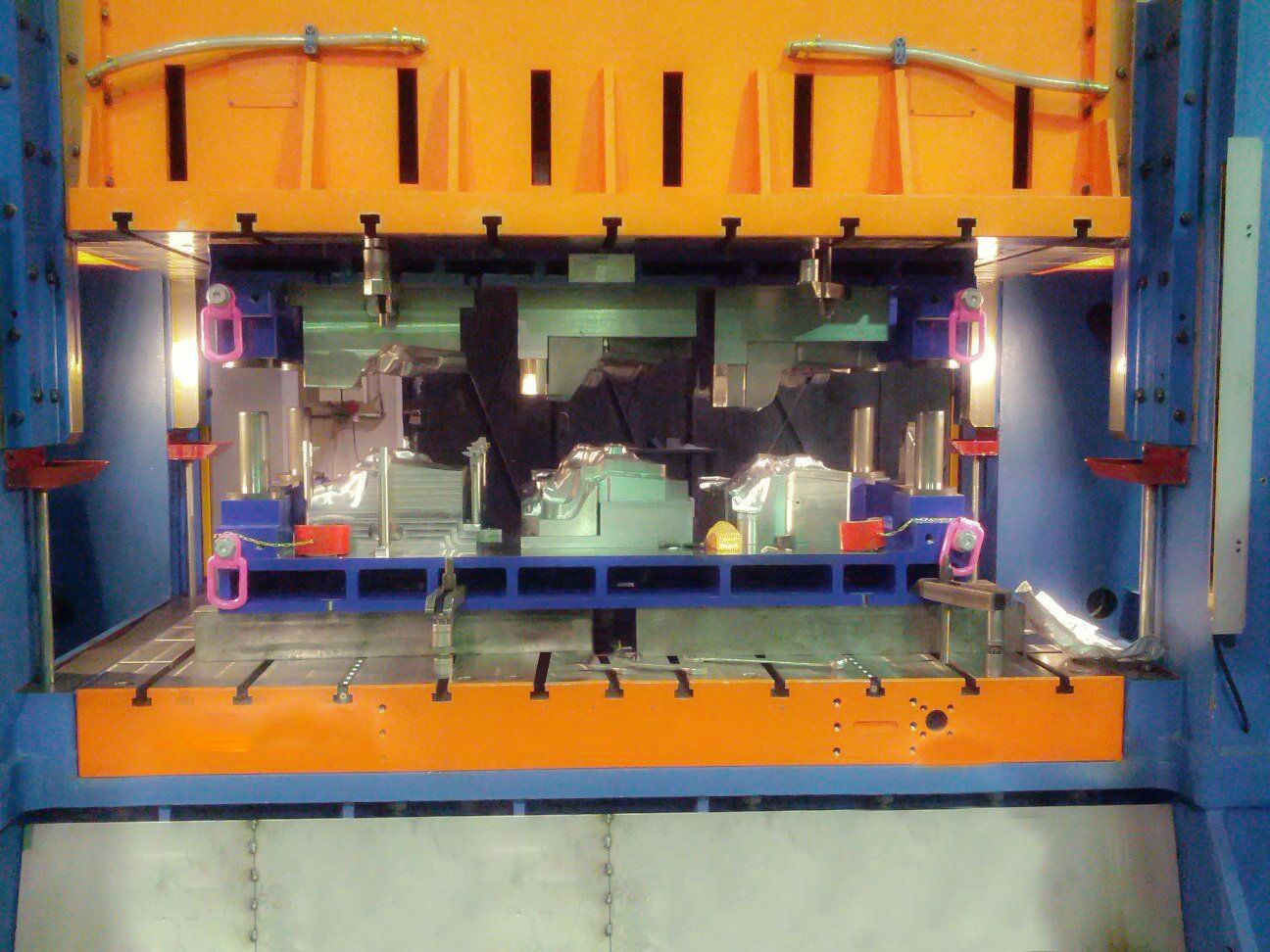

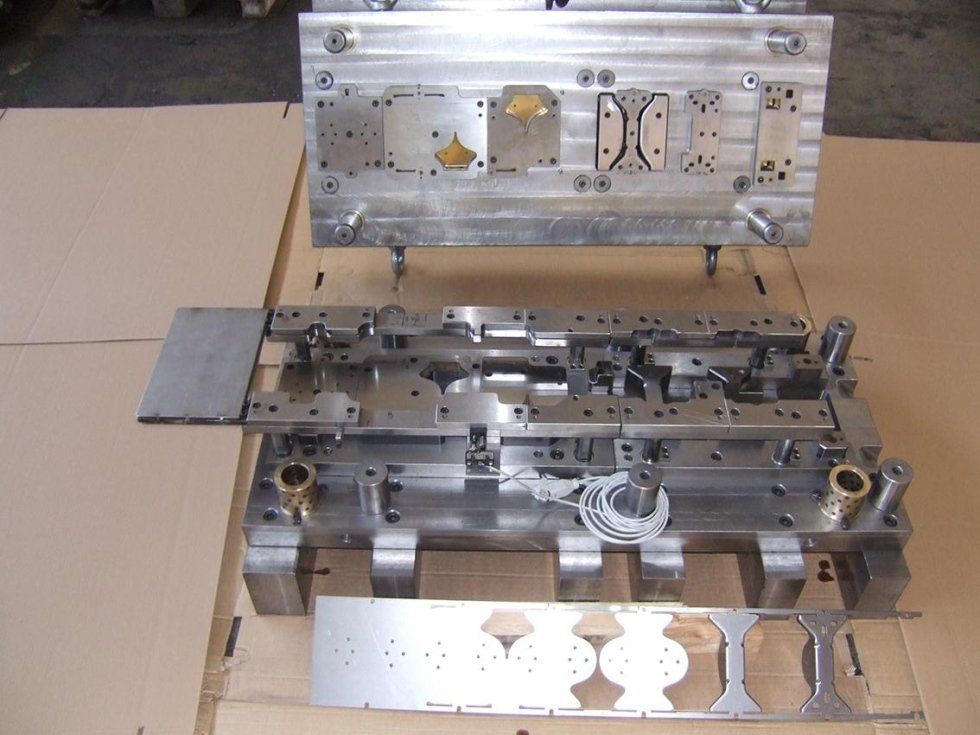

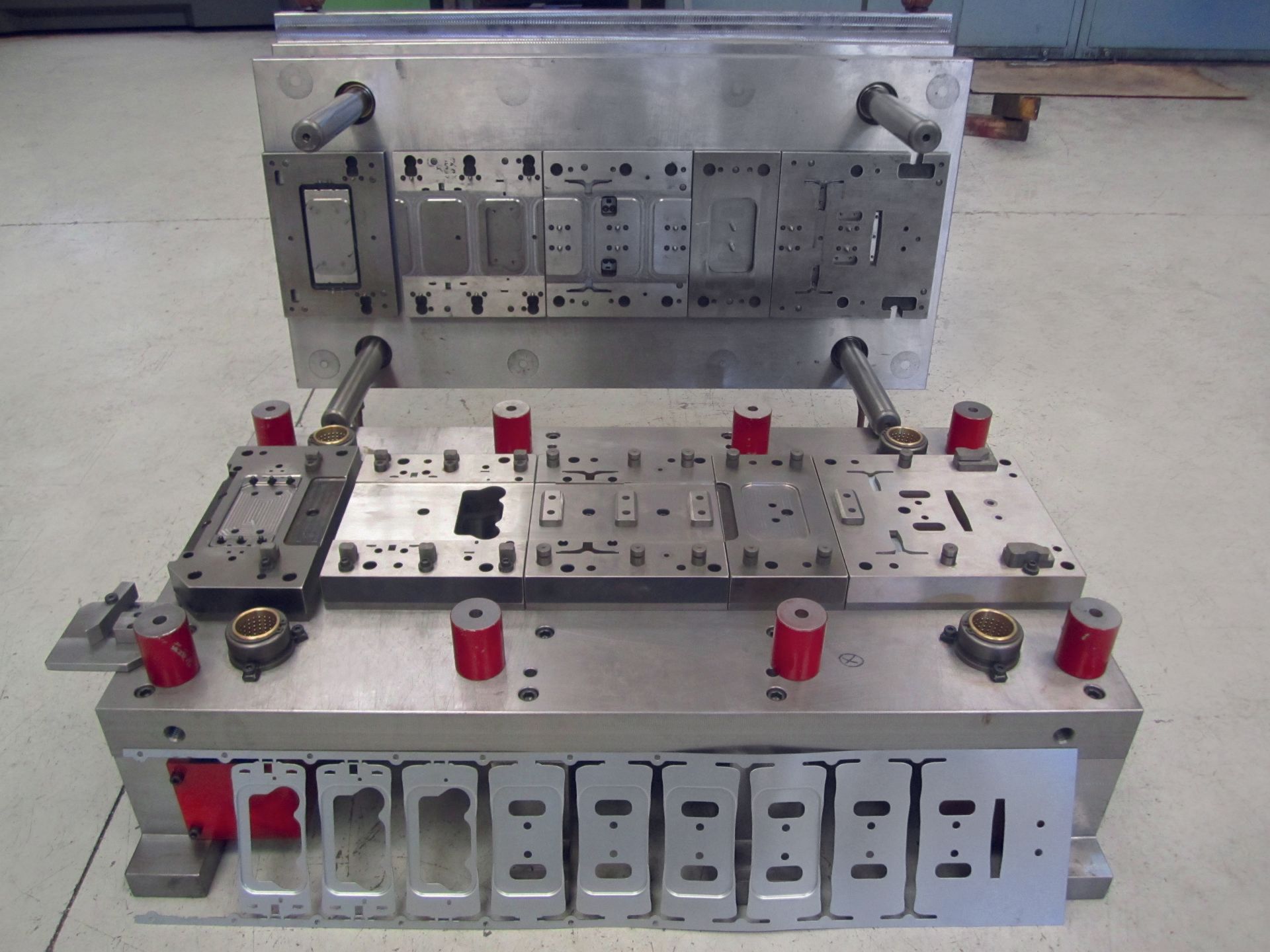

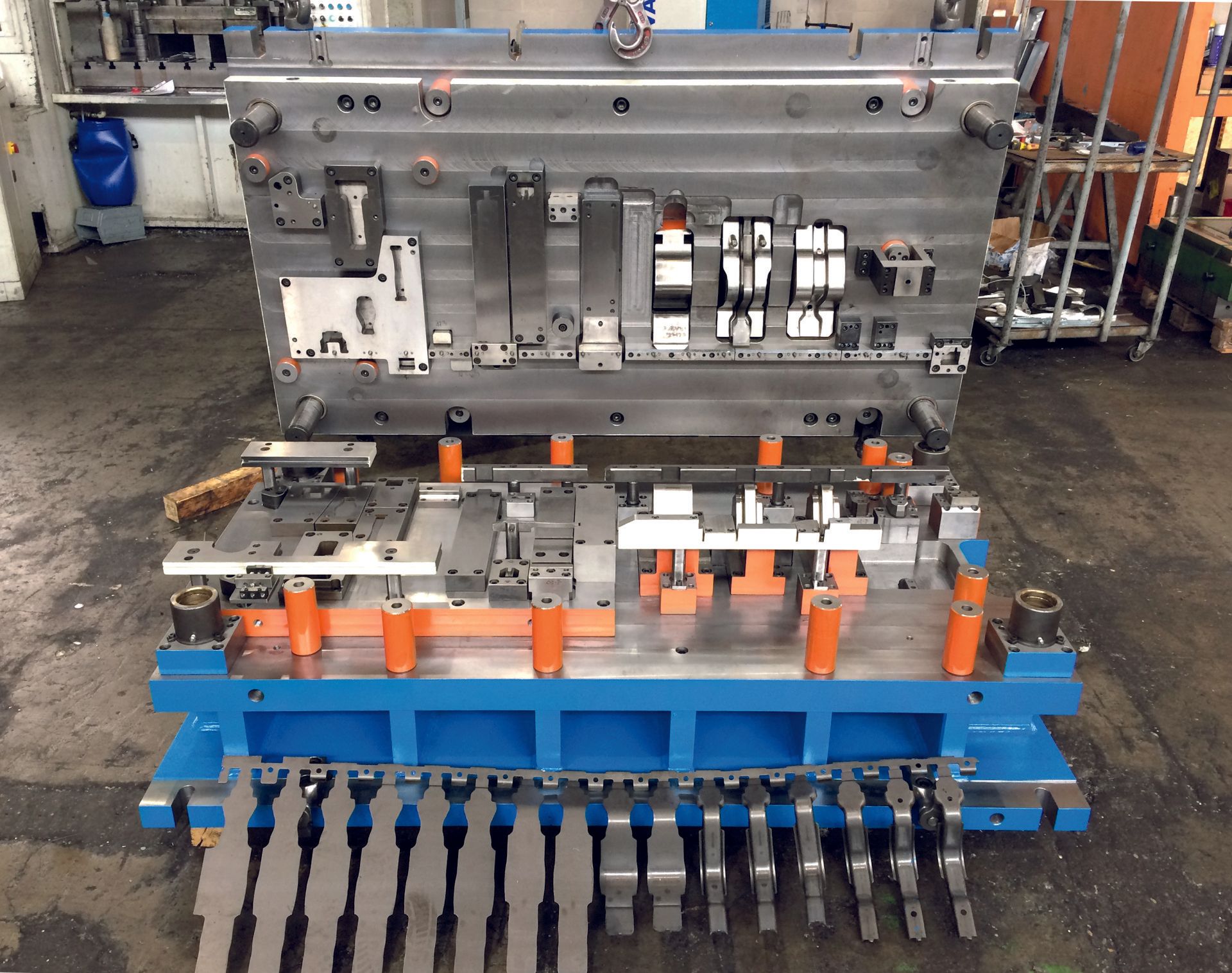

in the construction of dies for blanking, drawing and sheet metal deformation

since since 1969The experience gained in the sector, combined with constant technological evolution, has led to the creation of a highly efficient mold construction department, expanded and strengthened in 2017 to promptly respond to the demands of an increasingly demanding market. establishment, which today extends over an area covered by approximately 5,000 m², allows you to manage all operational phases internally, from design to delivery, keeping every single production aspect under control.

Mold Construction

The department is equipped with state-of-the-art CNC machinery, mechanical and hydraulic presses, automated systems, and CAD-CAM software for 2D and 3D modeling. This allows the company to produce progressive, block, and transfer molds with high quality standards and low margins of error. At the heart of the entire production process is the sheet metal mold design, which represents a strategic and essential step. The technical team analyzes the product design, selects the most suitable materials, and optimizes the geometries to achieve maximum efficiency during the blanking or drawing phase.

Thanks to a well-structured internal organization, each project is managed with care and flexibility. The client is supported from the preliminary stages to develop customized solutions, with functional prototypes and sized checks.the goal is to guarantee a final product

That perfectly meets the technical specifications, minimizing production times and costs.

Finally, the wide range of ancillary processes and treatments—including tempering, grinding, galvanizing, and painting—makes OLMEC a complete partner for those seeking reliability, precision, and expertise. Mold design

It is not just a technical activity, but an integrated service that combines consultancy, experience and technology to satisfy the most demanding sectors: automotive, electromechanical, construction, household goods and many others.

Consulting and feasibility study

The OLMEC technical department offers aadvanced consultancy and feasibility study service, designed to assist the client

throughout the initial phases of the project. The process begins with an in-depth analysis of the product to be produced, followed by an evaluation of the most effective technical solutions based on the type of processing required. The technical office works with CAD/CAM platforms to develop three-dimensional digital models, with detailed simulations of the production cycles and the material's behavior during molding.

This phase is essential to ensure precise planning, aimed at preventing critical issues and optimizing costs and time. OLMEC supports the customer in the choice

from the geometries

ideals, in the selection of materials

and in the cost-benefit analysis for each specific industrial application. The result is a comprehensive project, consistent with production needs and the technical characteristics of the finished product.

The consultancy also includes the creation of construction drawings and detailed technical specifications, which are shared with the client for any revisions before moving on to the operational phase. Continuous dialogue with the client allows for real-time adaptation of every element of the project. sheet metal mold design, ensuring maximum flexibility and control over functional requirements.

In addition, the service includes a careful assessment of industrial feasibility, with particular attention to optimizing mass production. Each technical proposal is based on dimensional calculations, mechanical tests, and realistic estimates of the mold's performance under operating conditions. In this way, sheet metal mold design results in a solid foundation

to obtain an efficient, durable and consistent mold with the most high quality standards in the sector.

Request information

Mold design and engineering are crucial phases of the process, requiring close collaboration between the technical department and the client. Trust the OLMECSRL team; contact the company by phone or email. A representative will respond promptly and provide an initial professional consultation.